PDU and Power Strips?

PDU & Power Strip

Both PDUs and standard household power strips are designed for splitting and distributing power to multiple attached devices. They both have multiple electric power outlets and an inlet with a power cord.

Generally speaking, a PDU (Power Distribution Unit) is responsible for controlling and distributing stable power; it is specially designed for industrial use. While a Power strip is designed to be used at homes, offices and many other areas in our daily life.

What are the actual differences between these two power devices? Which one is better, more stable and reliable? Can we apply standard power strips to racks in server rooms or data centers?

Let’s explore more about the difference of these two essential power products.

Differences between PDUs and Power Strips

♦Configurations

Outlet types

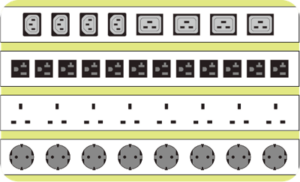

In addition to domestic outlets (US Nema, UK BS1363, Schuko, etc.), PDUs offer industrial-grade outlets, such as IEC C13 / C19, that aren’t available on standard power strips which only offer country specific domestic outlets.

Outlet quantity

Common PDUs configurations offer 4 to 48 outlets. Power strips typically only have 2 to 8 outlets due to amperage & power quality limitations when splitting the inlet into many different outlets.

Inlet types

Similar to outlet types, PDUs and power strips both support domestic inlets (US Nema, UK BS1363, Schuko, etc.), but PDUs can also support industrial-grade inlets such as IEC 60309, NEMA L6-30P /20P, etc.

Cordset thickness

Thicker cables offer lower resistivity to the flow of electricity and are able to carry more current (amperage). Standard power strip’s cordset thickness is normally around 1.5 mm² / 14 AWG, while PDU’s cordset thickness starts from 1.5 mm²/ 14AWG and goes up to 10 mm² / 6 AWG (depending on the Amp value supported by the PDU).

Inlet / cordset quantity

Standard Power Strips will always feature a single cordset, whereas PDUs support single cordset and inlet for most configurations, but are also available in configurations (e.g. Dual Feed PDUs, and Automatic Transfer Switch (ATS) PDU) that come with dual cordset and inlet to add power redundancy to attached devices.

Power phase (Voltage)

Power strips offer 110V / 208V / 230V single-phase power, which is generally applied in individual residences, shops, commercial offices, etc. As for PDUs, in addition to supporting 110V / 208V / 230V single-phase power for the applications in offices, server rooms, etc., 208V / 400V three-phase power is also available for data centers or other industrial applications. Three-phase PDU delivers 1.7 times more power capacity than Single-phase; it is more suitable for heavy workloads and power-hungry applications.

Customization

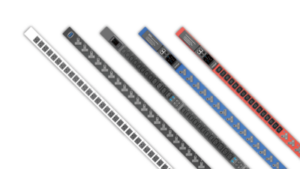

In addition to having standard stocked PDU models, Austin Hughes offers every PDUs chassis ‘built-to-order’ to fit the needs of any application – the outlet, inlet, voltage, current, types of connections, and colors can all be customized. Standard power strips are rarely available with customization.

♦Applications

Usage environment & application areas

A PDU is designed to fulfill IT and data center environments’ industrial needs; it is especially designed for power distribution to IT servers, network switches, KVM, LCD drawers, fan systems, and other rackmount equipment. In addition to the power quality & power quantity requirements, some of the advanced features in PDUs described below makes them necessary for mission critical applications. If the environment requires a lighter workload, such as shops, homes, and offices, standard power strips may be sufficient. They are commonly applied for power distribution to desktop computers, AV entertainment systems, lighting systems, and domestic appliances.

Installation

A PDU is typically mounted to IT server racks, while power strips do not have any specific installation location.

♦Physical Differences

From factor

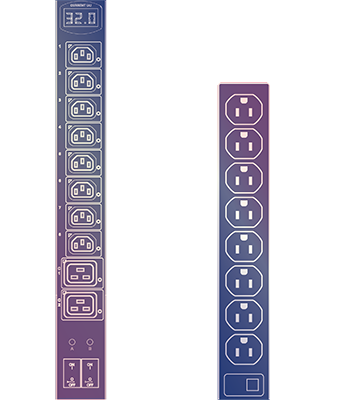

PDUs are available in vertical 0U configuration, mounted to the back of a rack without taking rack space, or are mounted in 1U / 2U of horizontal 19” rack mount space. Power strip don’t have any specific form factor, and are most commonly in the shape of a bar.

Materials

The rigid nature of steel or extrusion materials are standard for industrial usage with PDUs. Power strip are almost always made of plastic.

♦Safety devices

Downtime can be incredibly expensive in data centers – on average 1 million dollars per time / $11,000 per minute -, and can also lead to data loss in mission critical applications. The quality of the power is also very important. A PDU protects the attached devices from unexpected power quality issues and electrical disturbance, and greatly prolongs the devices life.

Fuse / MCB

PDUs are bundled with an industrial graded resettable fuse or magnetic circuit breaker, to ensure the protection of attached devices from power quality issues. In comparison, power strips typically don’t feature any power safety features, but more advanced units can be bundled with a simple fuse or circuit breaker.

Extra safety devices

There are varieties of safety devices options for PDU, such as high quality surge protectors, Electro Magnetic Interference (EMI) filters, a Residual Current Monitor (RCM), a Earth-leakage Circuit Breaker (ELCB), and much more. As for power strips, more advanced models may be bundled with a surge protector, which may prevent fires but may not fully protect the attached devices.

♦Advanced functions & features

A basic PDU is similar to standard power strip, with the addition of choices in power type and amount, outlet / inlet types, and more safety requirements, but PDUs are also available with Intelligent features (Intelligent PDU / iPDU) which feature much more control & monitoring options over attached devices, and come with more advanced accessories.

Meter

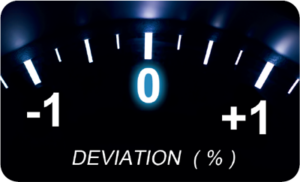

A Local meter is available for Metered & Intelligent PDU models. Austin Hughes meters feature a billing grade meter accuracy up to within +/- 1% of real time use, which is necessary for industrial applications.

Remote access

Intelligent PDU models are available for remote management over IP. Advanced iPDU design allows cascading of a group of intelligent PDUs to save the network IP address and to ease management of power devices.

Connection

Wired or wireless connections are available for remote access to Austin Hughes PDUs. There are serval IP access methods in our Intelligent PDUs that allow you to manage devices through software, including in a local wireless network or remotely through our wired or wireless dongles. Cascading is also be supported for linking a group of intelligent PDU.

Power management

Management software and SNMP for integration to third party DCIM are both available for Austin Hughes intelligent PDUs. The remote management areas include circuit-level or outlet level switching, alarm alert, scheduling, and many more advanced settings.

♦Extra accessories

Sensors

Austin Hughes PDUs are available with a large variety of environmental monitoring sensors, including a smoke sensor, temperature & humidity sensors, different types of door sensors, shock sensors, water leakage sensor, and more.

Outlets & power cords

Austin Hughes PDUs are available with a large variety of different power cords and outlet customization, including Lockable IEC outlets/cables, colored outlets/cables, and fused IEC outlets.

Types of PDU

PDUs come in various types for different applications; the common models in the market:

- Basic PDUs

- Intelligent PDUs

- Metered

- Monitored

- Switched

- Automatic transfer switch (ATS)

Austin Hughes offers excellent PDUs with over 4600 configurations and 8 colors to fit any need.

Explore Austin Hughes PDUs

All Austin Hughes Solutions are available for global supply with customer specific versions. Please contact your local office for further details.